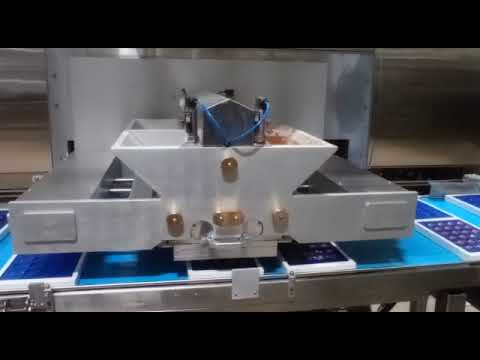

One Shot Depositor

CHOCOLATE STORAGE INNOVAS QUATTRO 156

• Innovas QUATTRO 156 series chocolate depositor is designed for high-capacity businesses.

• One-shot depositor is equipped with the latest technological equipment and is designed to obtain a perfect filling.

• While filling one-shot, a perfect filling is ensured by moving from bottom to top. With its double chamber structure, cream and chocolate can be deposited at the same time if desired.

• It provides the opportunity to make thin chocolate shell and 80% cream filling in filled chocolate.

• It provides easy cleaning with its detachable structure.

• It performs filling without stopping by following the chocolate mold advancing on the band.

• If there is no mold under the depositor, the pistons do not deposit the product.

• It provides smooth motion thanks to OMRON motion controlled servo motor in X and Y axis.

CAPACITY

• Maximum capacity 2400 kg/h, 16 strokes/min.

• Piston diameter 16mm

• Maximum piston stroke 80mm

• A total of 156 pistons are available for depositing 78 chocolates and 78 creams.

PRODUCTS

• Filled tablet

• Filled bar

• Filled chocolate ball

• Praline

• Chocolate

• Madeleine

TECHNICIAL SPECIFICATIONS

• Body material is produced from Al 7075 series mold aluminum in order to minimize the amount of deformation on it after long-term use.

• Aluminum anodized coated for high resistance against chemical cleaning elements.

• Silicone heaters bring flexibility to the system, and the use and simplicity of silicone heaters come to the fore compared to conventional aqueous systems.

• The mixer speeds can be adjusted to different values according to the types of chocolate, and at the same time, position control can be made in the mixer to prevent air bubbles in the chocolate.

• With OMRON servo motion control, position information is not lost in power cuts. In this system, it is sufficient to do the reset settings of the servos mechanically once instead of using the sensor. With this feature, the system is protected against possible sensor errors.

• System sensitivity is 60% higher than classical lever systems with rack type mechanical movement. The mechanical response to the movements of the servo is highly sensitive. In this way, the system can reach high grammage sensitivities.